Since 1970 a passion for stainless steel

Fratelli TASCA is a Venetian company with over 50 years of experience in steel processing.

In 1970 Livio Tasca opened his first workshop for the design and production of molds for cold sheet metal deformation.

In the following decades and with the arrival of new generations, the company specialized in the production of stainless steel sinks and tubs for domestic kitchens, and became a trusted and competent partner of the most famous brands in the sector.

Fratelli TASCA reached an important milestone in 2005, with the creation of its first tub with 12mm radiused corners, obtained through welding. But the decisive turning point came in 2018, thanks to the creation of the TASCA® brand and the industrial conversion of the company, allowing Fratelli TASCA to finally emerge in the panorama of Italian industry as a quality manufacturing reality and at the forefront of production technologies.

Today Fratelli TASCA is a modern production plant based in Possagno (Treviso), which extends over a covered area of 7,000 square meters, dedicated exclusively to the design, development and production of sinks and tubs for domestic kitchens. With its collections, TASCA covers every style of kitchen, ranging from traditional sinks to design products, from workstations to minimalist style tubs. Anticipating market trends, Fratelli TASCA constantly modernises and expands its range of products, exploring new techniques and materials, but remaining faithful to its stainless passion for steel.

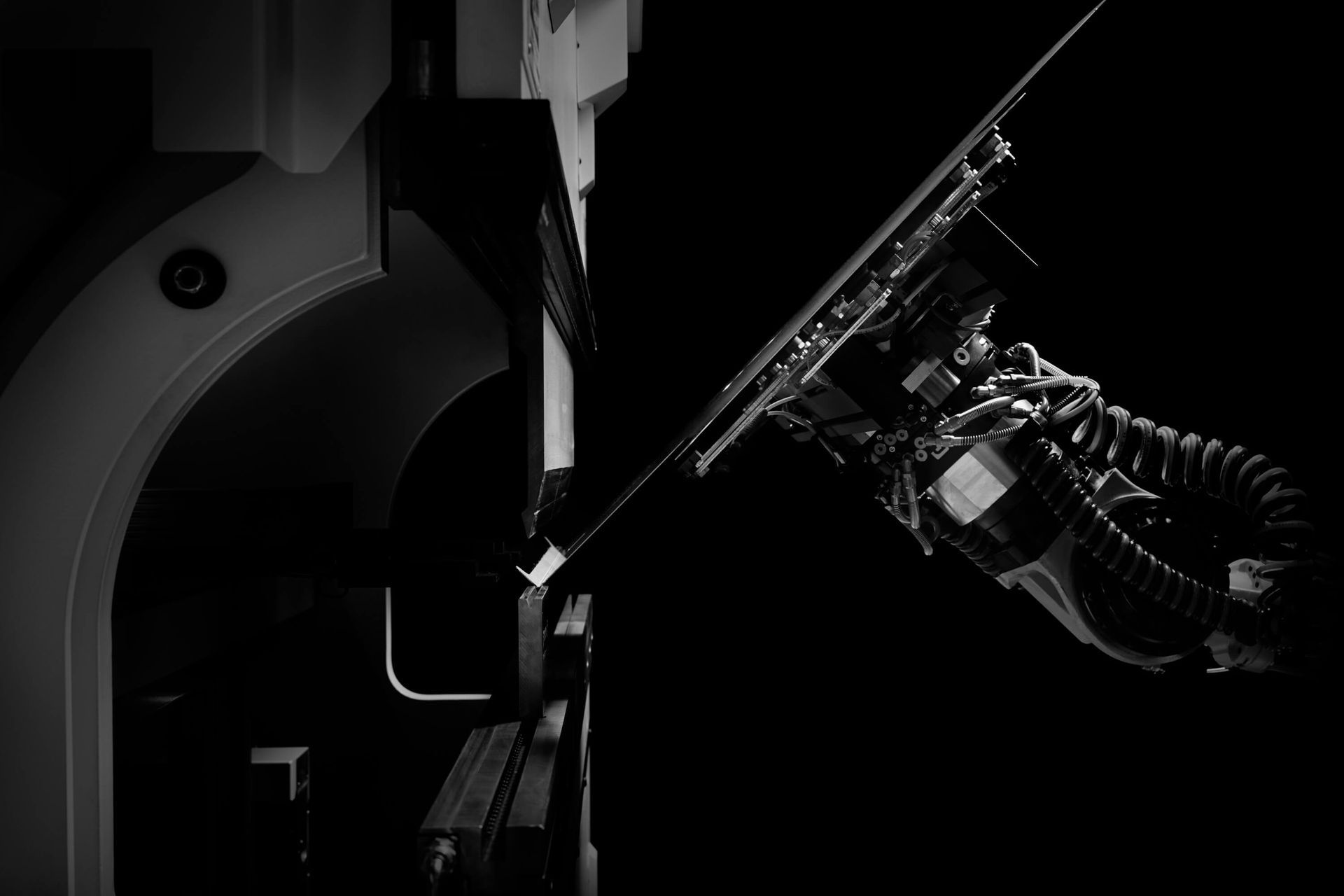

factory 4.0

Thanks to their ingenuity, technical skills and a strong sensitivity for design, Fratelli TASCA has renewed the concept of the sink itself, going beyond the definition of a “handmade” artisanal product and implementing the new concept of an “industrially manufactured” sink.

The result is a high-quality, designer sink, mass-produced by highly technological machinery. Attention to detail, perfect construction and design place TASCA sinks in the tradition of Made in Italy manufacturing, while the integration of intelligent digital technologies in the production process projects them into the future, in step with the highest standards of precision and speed.

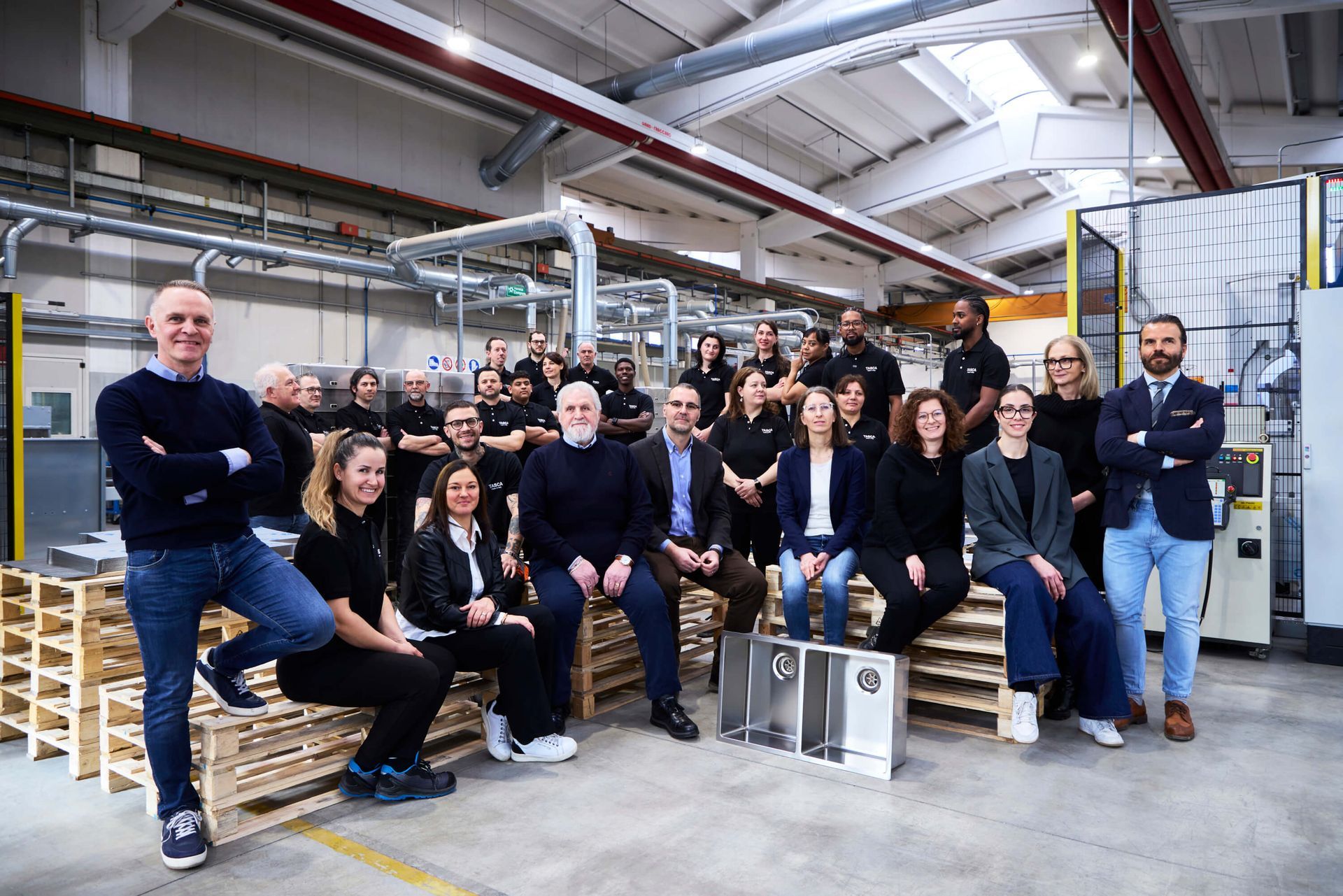

human values and identity

Thanks to an expert and qualified team, Fratelli TASCA takes care of every phase of the creation process, from design to the production of the finished product.

Each TASCA product is designed and manufactured in Italy, respecting human resources and our planet. Fratelli TASCA adopts an inclusive hiring policy, abhors child labor and guarantees adequate working conditions and wages for its collaborators, promoting the professional growth of each worker.

sustainability

TASCA takes care of environmental sustainability throughout the entire life cycle of the product: selecting recycled and regenerable raw materials, such as stainless steel, preferring a “dry” processing, with a significantly lower need for water and energy resources compared to traditional methods; using packaging from responsibly managed sources, recyclable and free of polystyrene.

Stainless steel is 100% recyclable and is designed for almost infinite reuse and regeneration. In a circular economy perspective, Fratelli TASCA uses approximately 90% recycled steel for the production of its sinks and the steel processing residues are reintroduced into the supply chain to create new products.